Sparco

Engineering's Next-Generation DCS & ICSS Solutions

Empowering

Automation, Safety, and Data Intelligence for the Energy Industry

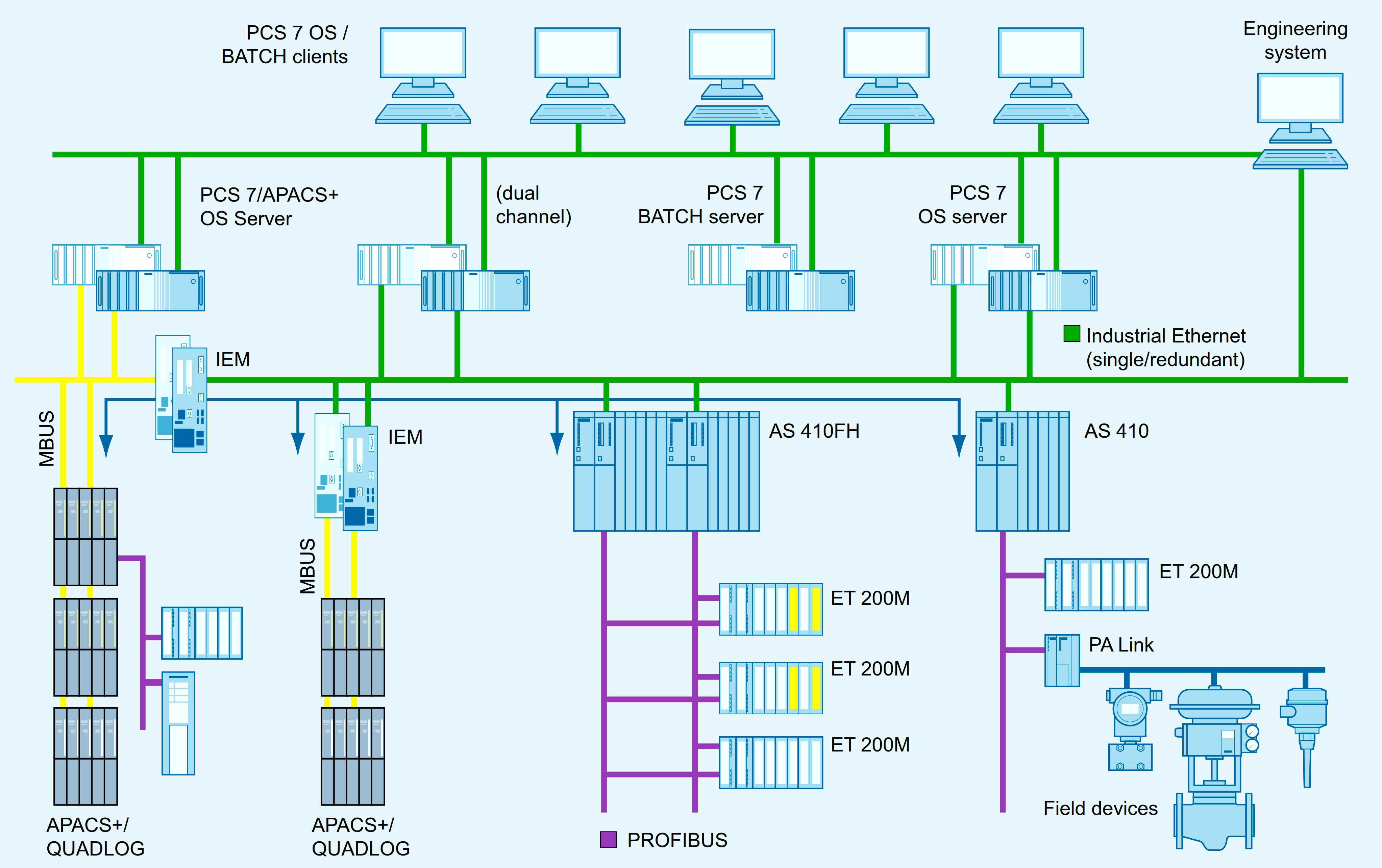

Sparco Engineering delivers cutting-edge Distributed Control Systems (DCS) and Integrated Control & Safety Systems (ICSS) designed to meet the complex demands of modern petrochemical facilities, oil & gas upstream and midstream operations, and gas compressor stations. Our systems are built around the latest generation of automation platforms and intelligent data management architectures, ensuring seamless integration, reliability, and performance across critical infrastructure. Distributed Control System (DCS)

Our

advanced DCS platforms serve as the digital backbone of process automation.

They integrate a full suite of operational functionalities into a unified

system, including:

- Human Machine Interface (HMI):

Intuitive and scalable graphical user interfaces for real-time plant

visualization and control.

- Advanced Process Control

(APC): Predictive and adaptive control algorithms to optimize efficiency

and minimize variability.

- Historian & Data

Archiving: High-speed, secure storage of operational data for analysis,

compliance, and performance tuning.

- Alarm & Event Management:

Prioritized, context-aware alarm systems to enhance operator awareness and

reduce nuisance alarms.

- Engineering Suite: Centralized

environment for configuration, diagnostics, versioning, simulation, and

lifecycle management.

Sparco

Engineering integrates globally recognized DCS platforms from leading OEMs such

as Yokogawa (CENTUM VP), Emerson (DeltaV), and ABB (800xA), tailored to

specific client requirements through our in-house team of certified engineers.

2.

Integrated Control & Safety System (ICSS)

Our ICSS

solutions unify Process Control Systems (PCS), Emergency Shutdown Systems (ESD),

Fire & Gas Systems (F&G), and High Integrity Pressure Protection

Systems (HIPPS) into a secure and resilient architecture.

Key

Features:

- Safety Instrumented Systems

(SIS) compliant with IEC 61508 / 61511

- Redundant, fail-safe PLCs and

I/O configurations

- Deterministic safety response

and segregation between control and safety layers

- Integration with DCS for

centralized HMI and diagnostics

This integrated approach improves system availability, facilitates rapid troubleshooting, and ensures compliance with the most stringent industry safety standards.

3.

Digitalization and Smart Data Management

Sparco Engineering enhances traditional control systems with intelligent digital layers, turning raw process data into actionable intelligence.

Our capabilities

include:

- Edge and Cloud-Based Data

Analytics

- Predictive Maintenance through

AI/ML Algorithms

- Digital Twin Integration for

Simulation and Training

- Cybersecure Remote Monitoring

and Operation

- Centralized SCADA and Data

Historian Systems with OPC-UA Architecture

By

leveraging IoT sensors, secure industrial protocols, and analytics platforms,

we help clients achieve real-time insight into operational KPIs, asset health,

and process optimization opportunities.

4.

Sector-Specific Expertise

Petrochemical

Plants

- Batch and continuous process

automation

- Integration with refinery

management systems (RMS)

- Energy efficiency and

emissions tracking

Oil &

Gas (Upstream & Midstream)

- Wellhead control automation

- Pipeline integrity monitoring

- Remote terminal units (RTUs)

for unmanned sites

Gas

Compressor Stations

- Turbomachinery control (TMC)

integration

- Fuel gas metering and

conditioning systems

- Vibration and surge protection

interlocks

Why Choose

Sparco Engineering?

- Decades of experience across

upstream, midstream, and downstream sectors

- In-house control room,

substation, and field device integration

- Cybersecurity by design

(ISA/IEC 62443 compliance)

- Lifecycle support from FEED to

commissioning and O&M

Sparco Engineering’s DCS and ICSS platforms are engineered to deliver safety, reliability, and intelligence, empowering our clients to operate smarter, safer, and more sustainably in today’s digital energy landscape.