Nitrogen Gas Generation

Define the Requirements

Nitrogen gas generation systems are still the most efficient way to consistently supply high purity instrument gas especially for the oil & energy industry including onshore oil refinery plants and offshore oil platforms where the environment is harsh and safety is of the utmost priority. Petro Gasgen’s range of nitrogen gas generation systems including PSA nitrogen generators and membrane nitrogen generatorsare specifically designed to be robust and reliable while operating 24/7 in some of the toughest environments imaginable.

How It Works?

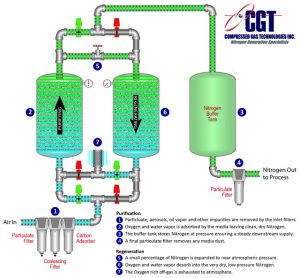

The main operating principle of a PSA nitrogen generator is the Pressure Swing Adsorption principle which it utilizes to produce a steady stream of nitrogen gas from compressed air. Air is passed through a Carbon Molecular Sieve (CMS) which is a column of tightly packed material at pressure made of carbon. The larger oxygen and other molecules are adsorbed by the CMS leaving the smaller nitrogen molecules to pass through the CMS and form high purity nitrogen. The contaminants leftover are vented from the CMS after a pre-set time with the on-line tower automatically switching to regenerative mode.

A membrane nitrogen generator operates by filtering normal compressed air and passing it through a bundle of hollow membrane fibers that are technically advanced. Selective permeation is then used to separate the nitrogen from the feed air where oxygen and water vapor are exhausted safely to the atmosphere while pressurized nitrogen gas is channeled to the distribution system. A combination of multiple membrane bundles gives birth to an infinite number of flow/purity ranges that can satisfy any industrial need for nitrogen gas generation.

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025