Mercury Removal

Define the Requirements How It works

Mercury removal unit – how it works & key benefits – got repetition on the website.

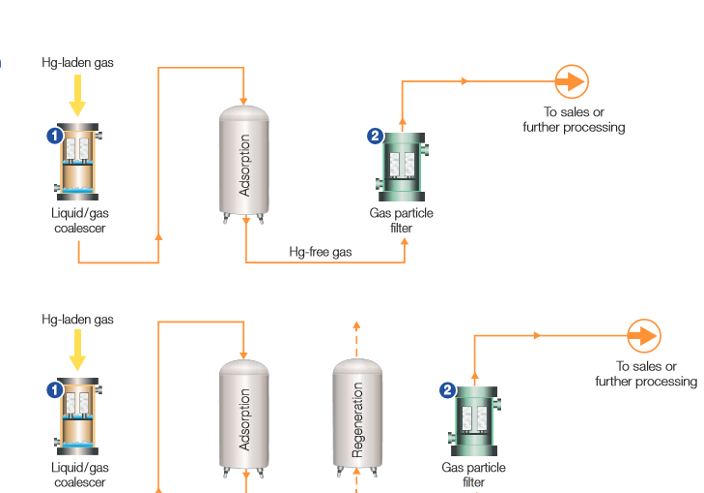

How it works:

The most common processes used for treatment of mercury-contaminated water are

precipitation, adsorption, membrane filtration, and biological treatment. Each of these water

treatment technologies offers certain advantages that depend heavily upon the process conditions of a given installation.

To achieve the best possible performance, a facility will need to carefully consider which constituents are present in addition to mercury, as well as

factors like stream pH, temperature, flow rate, volume, and BOD. Additionally, a facility will need to consider the target mercury concentration, as

not all treatment technologies are capable of reducing mercury levels down to meet water

quality goals. It is also worth noting that wastewater discharge standards are subject to

change, and planning for future compliance is important when investing in water treatment

equipment.

Benefits:

–Proven plant, equipment, and process protection

– Environmental compliance Reduced toxicity and risk

– Minimized environmental risks

– Simple, reliable, and predictable operation requiring minimal operator attention

– Technical support throughout operation Industry-leading performance warranty

⦁ Nitrogen Gas generation – key benefit

⦁ Staff Safety

⦁ Cost Saving

⦁ Environmental Impact

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025