TEG DEHYDRATION PROCESSS

Define the Requirements

One of the major inconveniences for plant operators in the oil and gas manufacturing industry is the constant need to figure out ways to eliminate contaminants and deliver products with the best purity. A major unwanted contaminant associated with natural gas is water vapor. Petro Gasgen’soffers standard or custom engineered triethylene glycol (TEG) dehydration units to remove water vapor from natural gas and natural gas liquid (NGL) streams which helps prevent hydrate formation and corrosion and increase efficiency of pipelines. Petro Gasgen’s team of highly trained engineers and technicians fabricate and install complete TEG dehydration units that include inlet scrubbers, contact towers, reboilers, surge tanks and flash separator to suit client specifications and requirements.

How It Works?

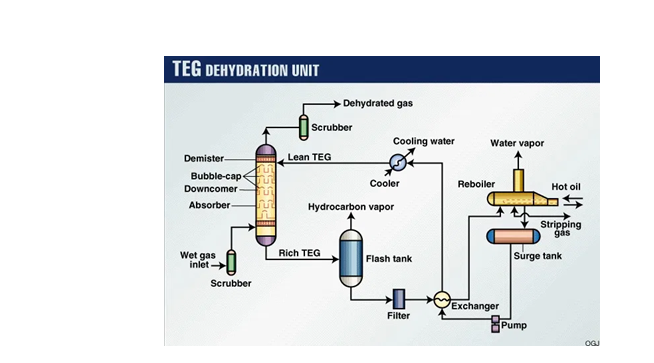

A usual TEG dehydration unit incorporates natural gas drying phases with glycol regeneration processes. First, free water is eliminated from wet natural gas by directing the wet natural gas through a feed gas inlet on the gas scrubber. This helps to remove most of the suspended water, free hydrocarbons and particulate impurities in the gas stream. Next, the natural gas is channeled through the inlet at the bottom of a contact tower where it rises to the top of the column while being constantly in contact with glycol fluid. This helps to eliminate any residual moisture in the natural gas stream whereby the newly dried natural gas is channeled to storage tanks or other processing through an outlet channel at the top of the contact tower. The wet glycol that has absorbed the moisture in the contact tower is then directed to a flash separator to remove accumulated water vapor, particulate impurities and oils. A reboiler is then used to separate the absorbed water from the glycol by distillation. This process converts the wet glycol into lean glycol that is channeled back to the contact tower for further natural gas dehydration cycles.

Key Benefits

- Increased operational versatility

- Reduced operating costs compared with conventional desiccants

- On-site equipment orientations and training for client personnel

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025