Carbon Dioxide Removal

Define the process

The removal of carbon dioxide, CO2 which is commonly found in most natural gas fields, in concentrations of up to 80 percent volume is vital to protect against downstream corrosion and maintain fuel point value. Petro Gasgen’s offering of CO2 removal technologies include membrane removal system, fluor solvent offshore process and acid gas fractionation with methanol system that can help ensure operators’ CO2 removal reliably meets their daily production quotas and equipment protection needs.

How It Works?

In a typical CO2 removal membrane system, the feed gas is first filtered to remove anyentrained liquids and aerosols. The gas then enters the membrane filters. The CO2 as well as the H2S and H2O permeate preferably through the membrane. The non-permeated gas, mainly CH4, remains at pressure and is the product gas.This technology combines high permeability with high hydrocarbon resistance, making it an attractive option for bulk carbon dioxide removal. In addition, the operation is highly flexible, it requires little maintenance, making it ideal for remote and offshore locations.

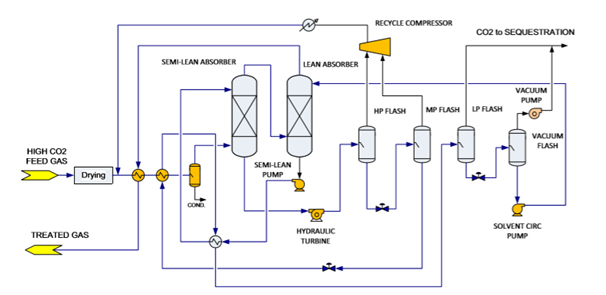

For fluor solvent offshore process, Pulverized Coal (PC) is used as the solvent because PC unit can operate with the low solvent circulation, recovering more hydrocarbon and is lower cost option when used to process high-CO2 gases. Refrigerant can be generated through theletdown of rich solvent using hydraulic turbine, eliminating external refrigeration requirement.

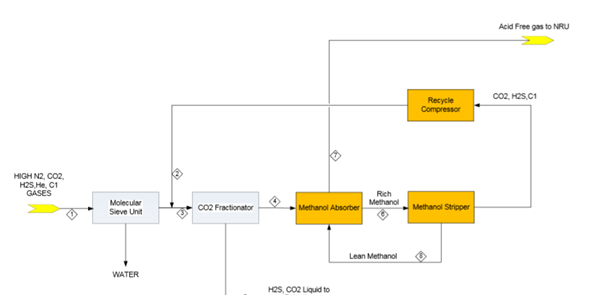

The acid gas fractionation with methanol system removes high acid gas stream using refrigerated fractionation configuration.

Key Benefits

I. Achieve or exceed natural gas production quotas via reliable CO2 removal from raw natural gases

II. Protect against fouling and blockage of flow paths by entrained solids

III. On-site equipment orientations and training for client personnel

Flour Solvent Offshore Process

In this process, we use Pulverized Coal (PC) as the solvent because PC unit can operate with the low solvent circulation, recovering more hydrocarbon and is lower cost option when used to process high-CO2 gases. Refrigerant can be generated by letdown of the rich solvent using hydraulic turbine, eliminating external refrigeration requirement.

Acid Gas Fractionation with Methanol System

We offer the system that will removed high acid gas stream using refrigerated fractionation configuration

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025