Gas Dehydration

Define the Requirements

Gas Dehydration – how it works & key benefits

How it works:

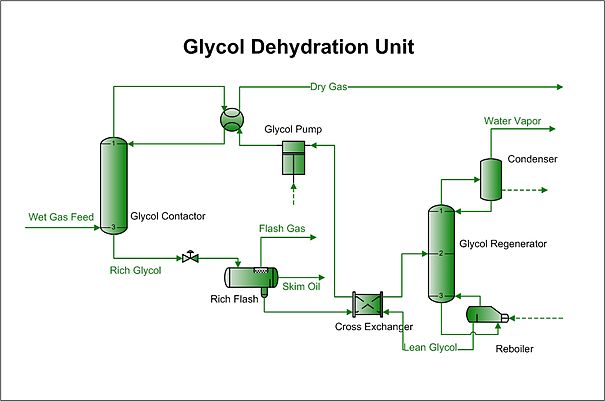

A TEG dehydration unit combined glycol regeneration and natural gas drying phases. First, water vapor-mixed natural gas is directed via a feed gas entrance on the gas scrubber to remove any free water present. This gets rid of free hydrocarbons, particle contaminants, and the majority of the water that is suspended in the gas stream. However, more drying is required because the natural gas is still regarded as “wet” at this point.

The last step involves sending the gas through connecting channels to a contact tower, where the drying process is completed. In a typical contact tower, liquid glycol that is moisture-free or “lean” is contained in properly constructed levels. Typically, natural gas is delivered from an inlet at the base of the contact tower, rising through it, and coming into continual touch with the glycol fluid at various heights. As the gas rises to the top of the column, any moisture that may still be present in it is drawn out, and a channel is waiting to transport the freshly dried gas to storage tanks or further processing. While this is going on, the contact tower’s glycol solution absorbs moisture and becomes “rich,” requiring regeneration. Wet glycol is removed through another outlet and directed to a regeneration process, while dry glycol is fed into the process through one inlet.

When “wet” glycol is directed into a three-stage flash separator to remove accumulated water vapour, particle contaminants, and oils, the process of reformulating lean glycol begins. Impurity-free glycol is transferred to a reboiler unit while the impurities are directed to storage tanks for later disposal.

How its Works

By distillation, the reboiler separates the absorbed water from the glycol. The boiling point of water is 212°F, while that of glycol is 550°F. Since ethylene glycol starts to break down at 404 degrees Fahrenheit, most operators keep their distillation processes between 212 and 400 degrees Fahrenheit. The “lean” or dry glycol is now prepared to be reintroduced to the contact tower for more natural gas dehydration cycles after any remaining water is removed as steam from it.

Key benefits:

⦁ Can be used to effectively dry natural gas

⦁ Have a broad range of efficient air-drying solutions useful in diverse industrial applications.

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025