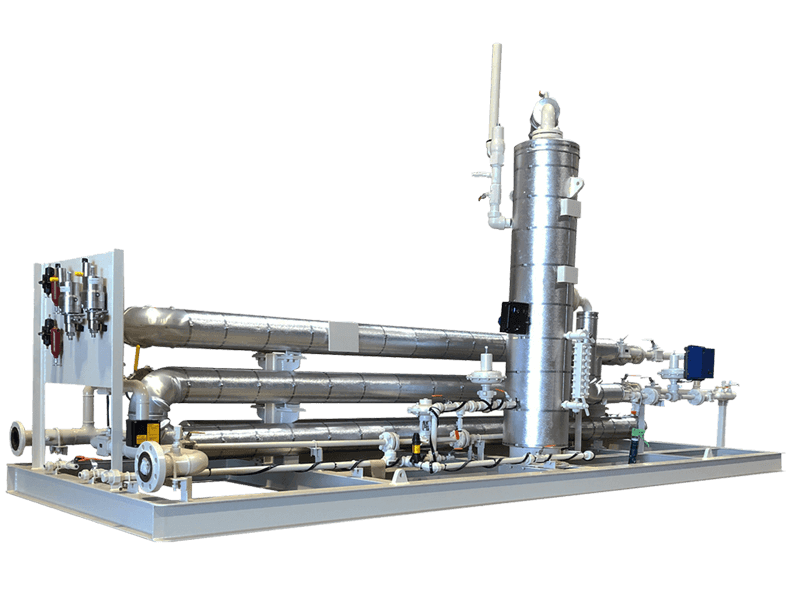

JT Dew Point Conditioning System

How it works

Accurate prediction of dew point pressures of natural gas is of the utmost importance for the gas industry as it is one of the gas quality specifications used for ensuring the safe transport and processing of natural gas. Hence, Petro Gasgen’s offering of a custom engineered and highly efficient Joule-Thompson (JT) plant helps to recover precious natural gas liquids (NGL) much more easily while also assisting to maintain the water and hydrocarbon dew point of a given production stream in accordance with local and international pipeline specifications. This self-contained, skid mounted system is perfectly suited for operating environments with short-term application and space limitations such as offshore oil platforms due to its ease of installation and starting up.

How its works?

The main components of a JT plant are gas/gas heat exchanger with hot gas bypass, cold separator, JT valve, methanol injection system and control system. Gas enters the JT plant and flows through the gas/gas heat exchanger followed by a gas/liquid heat exchanger.The gas then experiences a pressure drop and cools down to a low temperature after passing through the JT valve. The cold separator collects the liquid fallout from the JT valve and sends it to storage tanks while the remaining cold gas exits the JT plant by traveling back through the heat exchanger.

- Key Benefits

- Efficient separation and collection of precious NGL’s.

- High-efficiency heat exchanger

- Thermally insulated

- On-site equipment orientations and training for client personnel

- Reduced capital and operating expense

- Simple and safe maintenance

With over 25 years of experience, Sparco Engineering specializes in innovative solutions for gas generation, processing, and storage. Known for delivering successful EPCC projects, the company is now expanding into offshore EPCIC services, providing cutting-edge, cost-effective engineering expertise.

Quick Links

Featured Products

Latest News

- Doxxbet Casino Login App Sign Up January 17, 2025

- Gambling Apps Iphone January 17, 2025

- Epic Win Casino Online January 17, 2025

- Any Casinos Open In Australia January 17, 2025